Fitter Practical I, II Year

ITI Book Fitter Practical I, II Year is by Manish Sharma. Fitter Practical I, II Year is according to Latest NSQF Level. Fitter Practical I, II Year is according to latest syllabus of DGT(NCVT). Fitter Practical I, II Year is for I Year, II Year. Fitter Practical I, II Year is for ITI trade Fitter . Fitter Practical I, II Year have fundamental topic Fitter Trade Introduction Safety Precautions and First Aid, Fitter Skill Information - I, Fitter Trade Operations - I, Fitter Skill Information - II, Fitter Lathe Machine, Fitter Trade Operations - II, Fitter Trade Operations-III, Fitter Trade Operations - IV, Fitter Viva Practice

Fitter Trade Introduction Safety Precautions and First Aid

- Introduction

- Institute

- Types of Fitter

- Accident

- Safety Precautions while using Hand Tools

- Fire

- Safety Signs

- First Aid

Fitter Skill Information - I

- Important Tools and Instruments

- Marking, Measuring, Holding and Checking Tools

- Welding

- Common Faults of Gas Welding

- Layout of Fitting Shop

- Demonstration Sheet

- Uses of Various Tools

- Drawing Circle

- Using Number Punch

- Sheet Metal Tools

- Some Important Operations

Fitter Trade Operations - I

- Marking, punching, hacksawing of metals having different cross-sections and holding the job in vice.

- To practice hacksawing operation on the pipe and channel.

- To practice channel filing and parallel filing.

- To practice marking with steel rule and odd leg caliper.

- Marking off straight lines and arcs using scribing block and divider.

- Chipping flat surfaces along a marked line.

- To practice measuring, marking, punching, sawing and filing using try square.

- To practice the drilling and checking of marked plates of different shapes.

- To determine the center of round rod with the help of surface gauge and ‘V’ block.

- To practice marking, sawing, chipping, flat filing, chamfering and checking.

- To practice angular and radius marking by filing.

- To practice slot and oil groove chipping.

- To practice various types of file step making up to ±0.25 mm accuracy.

- To practice letter punch and number punch by forming concave and convex radius.

- To convert round rod into square rod by forging..

- To change round rod into hexagonal rod by forging.

- To practice the marking on sheets and cutting in straight line.

- To practice marking of curve and cutting with snip.

- To prepare various sheet metal joints

- To mark rectangular tray and flaps soldering-I.

- To practice rectangular tray and flaps soldering-II.

- To assemble ash tray.

- To prepare lap joint by brazing process.

- To practice 'T' joint by brazing.

- To practice straight cutting by hand gas cutting.

- To prepare the fusion runs with filler rod.

Fitter Skill Information - II

- Important Tools and Instruments

- Marking, Measuring, Holding and Checking Tools

- Uses of Different Tools

- Drawing Circle

- Use of Punch

- Tools and Instruments

Fitter Lathe Machine

- Introduction

- Parts of the Lathe Machine

- Lathe Machine Attachements

- Lathe Machine Operations

- Various Angles of the Lathe Cutting Tools

- Knurling

- Boring

- Chamfering

- Parting Off

- Eccentric Turning

Fitter Trade Operations - II

- To hold the job in a four jaw chuck and do facing operation on both the ends using knife tool.

- To measure the diameter using the steel rule and outside caliper.

- To do facing, turning and chamfering operation on the job, holding it in a three jaw chuck.

- To practice plain and taper turning, reducing and checking.

- To practice single edge step turning.

- To practice double edge step turning.

- To practice turning and taper turning operation to make a 'B' slot and form the mandrel, and practice knurling operation.

- To practice drilling, turning, boring and brush step boring on the job and recess cutting.

- Cutting the’ V’-groove on the lathe machine using a taping die and matching the nuts and bolts.

- Drilling through holes and filing the radius and the surface of the MS flat job with complete accuracy.

- To file the radial and conical surfaces with an accuracy of ±0.05 mm and fitting the radial and conical Workpieces.

- To practice double square and radius fitting.

- To practice square fitting, drilling and tapping.

- To practice straight fitting.

- To practice the triangular fitting.

- To practice radius and angular fitting.

- To make bracket while doing marking, bending, filing, drilling, riveting and checking alignment using try square.

- To practice drilling and tapping.

- To practice the universal state of holes and checking it while marking, filing, drilling, taping, drawing and stud fitting.

- To practice counter sinking, counter boring and reaming.

- To practice filing and scraping on the bearing surface with accuracy.

- To practice external and internal radial and angular fitting.

- Prepare the ± 0.04 mm dovetail sliding using lower pin and screws.

- To prepare parallel and angular matching, thread cutting and sliding fit by using die with precision of ± 0.04 mm.

- To assemble the parts of a machine.

- To repair the parts of the machine.

- Setting up of the arc welding plant and practicing arc striking.

- Welding the MS sheet using the filler rod or without using the filler rod as shown in the drawing.

- Making a bid in a straight line from a 10 mm thick mild steel plate placed in a flat position as given in the drawing.

- Making a square butt joint using the butt weld from the MS sheet in a flat state.

- To make the fillet weld (external corner joint) with a 3.5 mm mild steel sheet in a flat state according to the given drawing.

Fitter Trade Operations-III

- To practice triangular internal fitting.

- To practice hexagonal rod fitting.

- To make key and key ways on the shaft and fitting.

- To make a V-groove and slot.

- To make lap riveted joints.

- To make butt riveted joints.

- To practice drilling on the cylindrical surface.

- To practice scraping on the flat surface.

- To practice scraping on the curved surface.

- To practice scraping on the internal and angular surfaces.

- To prepare the assembly fitting of the dowel pin and the screw.

- To make a ± 0.02 mm sliding assembly using dowel pins and tap screw.

- To practice sliding fitting.

- To practice angular or radius marking through filing.

- To practice radius and straight step fitting.

- To practice triangular and slot fitting.

- To practice angular fitting.

- To practice dovetail fitting.

- To drill blind hole and through hole in the 'Y' fitting at certain angle.

- To practice double square and radius fitting.

- To practice tapping, reaming, counter sinking, counter boring and checking.

- To practice hexagonal fitting.

- To practice chamfering, drilling, tapping and internal fitting.

- To make a snap gauge with an accuracy of ± 0.2 mm.

- To practice radius fitting.

- To make centre gauge.

- To practice internal diamond fitting.

- To practice the spark test to determine the amount of carbon in steel.

Fitter Trade Operations - IV

- To practice 'H' fitting.

- To practice hand lapping of gauges.

- To practice hand reaming and fitting of taper pin, dowel pin, stud pin and bolt.

- To prepare the jig for drilling.

- To prepare 'V' block.

- To manufacture the adjustable wrench.

- To practice the pipe bending by hot/cold method.

- To cut the pipe using hacksaw.

- To practice the assembling of G.I pipe with standard pipe fitting.

- To service the gate valve assembly.

- To assemble the water tap.

- To service the globe valve assembly.

- To service the non-return valve assembly.

- To do maintenance of the fire extinguisher.

- To refill the fire extinguisher.

- To perform screw cutting and straight fitting.

- To study the manufacturing of tempering spring.

- To practice the tempering of spring.

- To practice the marking, cutting and drilling of stainless steel plate or aluminum metal without damaging the respective objects.

- To practice drilling and tapping on the brass and copper jobs.

- To fit the pulley on shaft and replace the damaged key with the new key.

- To repair and replace a damaged belt.

- To repair the broken gear teeth by the pegging and dovetail processes.

- To prepare a packing gasket from rubber or fiber sheet.

- To prepare the gasket packing using a hollow punch.

- To form various knots using ropes and removing the damaged ropes.

ITI Book Fitter Practical I, II Year is by Manish Sharma. Fitter Practical I, II Year is according to Latest NSQF Level. Fitter Practical I, II Year is according to latest syllabus of DGT(NCVT). Fitter Practical I, II Year is for I Year, II Year. Fitter Practical I, II Year is for ITI trade Fitter . Fitter Practical I, II Year have fundamental topic Fitter Trade Introduction Safety Precautions and First Aid, Fitter Skill Information - I, Fitter Trade Operations - I, Fitter Skill Information - II, Fitter Lathe Machine, Fitter Trade Operations - II, Fitter Trade Operations-III, Fitter Trade Operations - IV, Fitter Viva Practice

Fitter

ITI trade Fitter is powered by NCVT. ITI trade Fitter is a job oriented trade ITI trade Fitter is suitable for government job and private job. This ITI trade Fitter is very powerful for self-empowerment. This ITI trade Fitter is perfectly design to fulfill industrial requirement of Indian Industries as well as International industries.

Fitters have a wide scope of Employability ranging from self-employment, contractual employment to Industrial jobs. On successful completion of this course, the candidates shall be gainfully employed in the following industries:

- Production & Manufacturing industries.

- Structural Fabrication like bridges, Roof structures, Building & construction.

- Automobile and allied industries

- Service industries like road transportation and Railways.

- Ship building and repair

- Infrastructure and defence organizations

- In public sector industries like BHEL, BEML, NTPC, etc and private industries in India & abroad.

- Self employment

International Comparability

- Existence of any official document suggesting the comparability of the qualification with the qualifications in other countries is not known.

- However, ITI passed out trainees are getting employment in many Gulf countries, European countries, Australia, New Zealand, Singapore etc.

Progression Pathway

- Can appear in 10+2 examination through National Institute of Open Schooling (NIOS) for acquiring higher secondary certificate and can go further for General/ Technical education

- Can take admission in diploma course in notified branches of Engineering by lateral entry

- Can join as semi-skilled worker in the industry and can become supervisor after doing part-time diploma in relevant branch of Engineering

- Can join Apprenticeship programme in different types of industries leading to National Apprenticeship certificate (NAC) after which they will be employed in industry as skilled worker and can become supervisor after doing part-time diploma in relevant branch of Engineering

- Can join Crafts Instructor Training Scheme (CITS) in the relevant trade after which they will be employed in ITI/ Vocational Training Institute as instructor

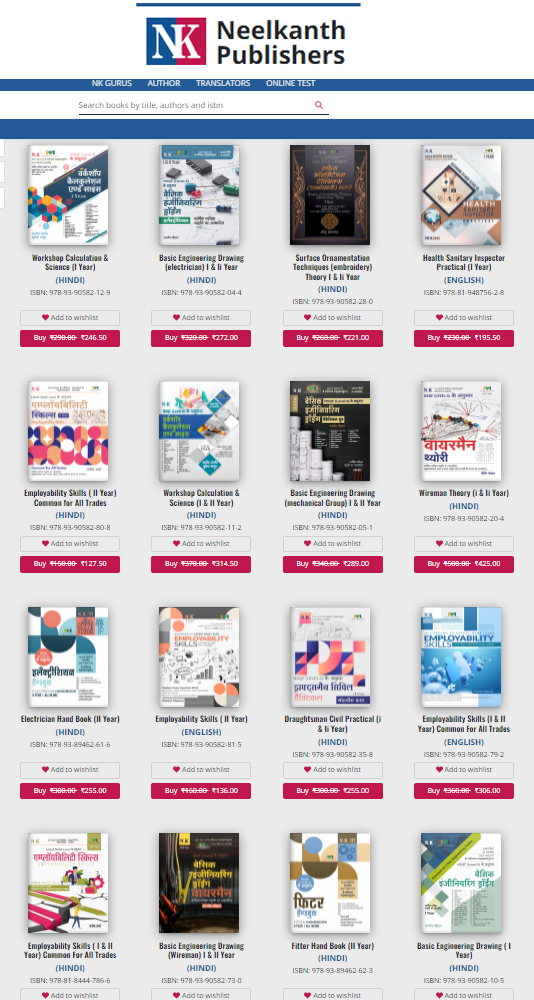

Neelkanth Publishers

Welcome to Neelkanth Publishers or NK as it is popularly known. In the last ten years, we have published more than 1100 titles and editions of text books, solved question papers in different segments including Engineering, ITI,Polytechnic and Skill Development. We believe in making quality books which are easy to understand, have lucid language and have simple and attractive illustrations. Our authors include some of the most well-known names in their respective fields. Though are books are prepared after painstaking and extensive research with numerous revisions for language and content, yet they are affordable for the masses and hence are popular in the entire country.

https://neelkanthpublishers.com/

ITI text and hand books

Trade Introduction, Safety Precautions and First Aid

Introduction

Institute

Types of Fitter

Accident

Safety Precautions while using Hand Tools

Fire

Safety Signs

First Aid

Skill Information

Important Tools and Instruments

Marking, Measuring, Holding and Checking Tools

Welding

Common Faults of Gas Welding

Layout of Fitting Shop

Demonstration Sheet

Uses of Various Tools

Drawing Circle

Using Number Punch

Sheet Metal Tools

Some Important Operations

Trade Operations - I

Marking, punching, hacksawing of metals having different cross-sections and holding the job in vice.

To practice hacksawing operation on the pipe and channel.

To practice channel filing and parallel filing.

To practice marking with steel rule and odd leg caliper.

Marking off straight lines and arcs using scribing block and divider.

Chipping flat surfaces along a marked line.

To practice measuring, marking, punching, sawing and filing using try square.

To practice the drilling and checking of marked plates of different shapes.

To determine the center of round rod with the help of surface gauge and ‘V’ block.

To practice marking, sawing, chipping, flat filing, chamfering and checking.

To practice angular and radius marking by filing.

To practice slot and oil groove chipping.

To practice various types of file step making up to ±0.25 mm accuracy.

To practice letter punch and number punch by forming concave and convex radius.

To convert round rod into square rod by forging..

To change round rod into hexagonal rod by forging.

To practice the marking on sheets and cutting in straight line.

To practice marking of curve and cutting with snip.

To prepare various sheet metal joints

To mark rectangular tray and flaps soldering-I.

To practice rectangular tray and flaps soldering-II.

To assemble ash tray.

To prepare lap joint by brazing process.

To practice 'T' joint by brazing.

To practice straight cutting by hand gas cutting.

To prepare the fusion runs with filler rod.

Skill Information

Important Tools and Instruments

Marking, Measuring, Holding and Checking Tools

Uses of Different Tools

Drawing Circle

Use of Punch

Tools and Instruments

Lathe Machine

Introduction

Parts of the Lathe Machine

Lathe Machine Attachements

Lathe Machine Operations

Various Angles of the Lathe Cutting Tools

Knurling

Boring

Chamfering

Parting Off

Eccentric Turning

Trade Operations - II

To hold the job in a four jaw chuck and do facing operation on both the ends using knife tool.

To measure the diameter using the steel rule and outside caliper.

To do facing, turning and chamfering operation on the job, holding it in a three jaw chuck.

To practice plain and taper turning, reducing and checking.

To practice single edge step turning.

To practice double edge step turning.

To practice turning and taper turning operation to make a 'B' slot and form the mandrel, and practice knurling operation.

To practice drilling, turning, boring and brush step boring on the job and recess cutting.

Cutting the’ V’-groove on the lathe machine using a taping die and matching the nuts and bolts.

Drilling through holes and filing the radius and the surface of the MS flat job with complete accuracy.

To file the radial and conical surfaces with an accuracy of ±0.05 mm and fitting the radial and conical Workpieces.

To practice double square and radius fitting.

To practice square fitting, drilling and tapping.

To practice straight fitting.

To practice the triangular fitting.

To practice radius and angular fitting.

To make bracket while doing marking, bending, filing, drilling, riveting and checking alignment using try square.

To practice drilling and tapping.

To practice the universal state of holes and checking it while marking, filing, drilling, taping, drawing and stud fitting.

To practice counter sinking, counter boring and reaming.

To practice filing and scraping on the bearing surface with accuracy.

To practice external and internal radial and angular fitting.

Prepare the ± 0.04 mm dovetail sliding using lower pin and screws.

To prepare parallel and angular matching, thread cutting and sliding fit by using die with precision of ± 0.04 mm.

To assemble the parts of a machine.

To repair the parts of the machine.

Setting up of the arc welding plant and practicing arc striking.

Welding the MS sheet using the filler rod or without using the filler rod as shown in the drawing.

Making a bid in a straight line from a 10 mm thick mild steel plate placed in a flat position as given in the drawing.

Making a square butt joint using the butt weld from the MS sheet in a flat state.

To make the fillet weld (external corner joint) with a 3.5 mm mild steel sheet in a flat state according to the given drawing.

Trade Operations-III

To practice triangular internal fitting.

To practice hexagonal rod fitting.

To make key and key ways on the shaft and fitting.

To make a V-groove and slot.

To make lap riveted joints.

To make butt riveted joints.

To practice drilling on the cylindrical surface.

To practice scraping on the flat surface.

To practice scraping on the curved surface.

To practice scraping on the internal and angular surfaces.

To prepare the assembly fitting of the dowel pin and the screw.

To make a ± 0.02 mm sliding assembly using dowel pins and tap screw.

To practice sliding fitting.

To practice angular or radius marking through filing.

To practice radius and straight step fitting.

To practice triangular and slot fitting.

To practice angular fitting.

To practice dovetail fitting.

To drill blind hole and through hole in the 'Y' fitting at certain angle.

To practice double square and radius fitting.

To practice tapping, reaming, counter sinking, counter boring and checking.

To practice hexagonal fitting.

To practice chamfering, drilling, tapping and internal fitting.

To make a snap gauge with an accuracy of ± 0.2 mm.

To practice radius fitting.

To make centre gauge.

To practice internal diamond fitting.

To practice the spark test to determine the amount of carbon in steel.

Trade Operations - IV

To practice 'H' fitting.

To practice hand lapping of gauges.

To practice hand reaming and fitting of taper pin, dowel pin, stud pin and bolt.

To prepare the jig for drilling.

To prepare 'V' block.

To manufacture the adjustable wrench.

To practice the pipe bending by hot/cold method.

To cut the pipe using hacksaw.

To practice the assembling of G.I pipe with standard pipe fitting.

To service the gate valve assembly.

To assemble the water tap.

To service the globe valve assembly.

To service the non-return valve assembly.

To do maintenance of the fire extinguisher.

To refill the fire extinguisher.

To perform screw cutting and straight fitting.

To study the manufacturing of tempering spring.

To practice the tempering of spring.

To practice the marking, cutting and drilling of stainless steel plate or aluminum metal without damaging the respective objects.

To practice drilling and tapping on the brass and copper jobs.

To fit the pulley on shaft and replace the damaged key with the new key.

To repair and replace a damaged belt.

To repair the broken gear teeth by the pegging and dovetail processes.

To prepare a packing gasket from rubber or fiber sheet.

To prepare the gasket packing using a hollow punch.

To form various knots using ropes and removing the damaged ropes.

Viva Practice

ITI Student Resume Portal

रिज्यूम पोर्टल का मुख्य उद्देश्य योग्य छात्रों की जानकारी सार्वजनिक पटल पर लाने की है जिससे जिन्हें आवश्यकता हो वह अपने सुविधा अनुसार छात्रों का चयन कर सकते हैं