Govt. ITI Talwar at Lahru

Govt. ITI Talwar at Lahru is situated in Kangra Himachal Pradesh. Govt. ITI Talwar at Lahru is Industrial Training Institute under NCVT Govt. ITI Talwar at Lahru. Location of Govt. ITI Talwar at Lahru is Tehsil jaisinghpur Kangra Himachal Pradesh.

Government ITI

Government ITI is leading educational organisatin in india. Teching facualty of Government ITI is suprimo. ITI is providing latest Job oriened cource for student. This Government ITI is powerd by 'Ministry of Skill Development and Entrepreneurship, Government of India for Craftsmen Training Scheme .

Himachal Pradesh

Plastic Processing Operator

ITI trade Plastic Processing Operator is powered by NCVT. ITI trade Plastic Processing Operator is a job oriented trade ITI trade Plastic Processing Operator is suitable for government job and private job. This ITI trade Plastic Processing Operator is very powerful for self-empowerment. This ITI trade Plastic Processing Operator is perfectly design to fulfill industrial requirement of Indian Industries as well as International industries.

The Plastic Processing Operator trade under CTS is one of the popular courses delivered nationwide through network of ITIs. The course is of one-year (02 semester) duration. It mainly consists of Domain area and Core area. In the Domain area (Trade Theory & Practical) impart professional skills and knowledge, while Core area (Workshop Calculation & science, Engineering Drawing and Employability Skills) impart requisite core skill, knowledge and life skills. After passing out the training program, the trainee is awarded National Trade Certificate (NTC) by NCVT which is recognized worldwide.

Plastic Processing Operator has a wide scope of Employability ranging from selfemployment, contractual employment to Industrial jobs. On successful completion of this course, the candidates shall be gainfully employed in the industries for following occupations:

- Supervisor and Foreman, Plastic

- Products Making

- Plastic Moulding Shop Supervisor

- Plastic Moulding Technician or Operator

- Moulder, Hand (Plastic)

- Plastic Products Making Operatives, Other

JOB ROLE

Supervisor and Foreman, Plastic Products Making; supervises various plastics product manufacturing processes and ensures proper use of men and materials. Studies specifications, arranges for materials, tools and equipment and guides setting of machines, tools, die, moulds, etc., according to type of article to be made. Gets trial piece made, checks it for dimensions, form and composition and makes alterations if necessary to ensure conformation to prescribed specifications. Supervises machine and other manufacturing processes such as extruding, moulding, injecting of material, etc. and ensures correct production. Maintains necessary records, ensures proper use of men and material and develops methods to minimise wastage. May conduct running repairs of machines and equipment to keep them in working condition.

Plastic Moulding Shop Supervisor; is responsible for supervising the PVC moulding and extrusion activities to create well formed PVC parts for automobile components, maintaining process parameters, conducting quality checks on output product, deploying manpower as per requirement, guiding operatives and technicians to complete the assigned task, maintaining a safe and healthy working environment on the shop floor and maintaining records related to production, rejections, material movement and manpower productivity for a line/shift

Plastic Moulding Technician or Operator; manages the specifications of the plastic and its granules, setting up and operating the moulding machinery and forming and finishing the output.

Moulder, Hand (Plastic); moulds plastics sheets into desired shapes in hand moulding press. Studies specifications for moulded product and assembles mould. Determines weight of charge, pressure, temperature and curing time for moulding; collects plastic sheets, cuts them to required size and heats them on electrically operated heater to soften for moulding; removes sheet when sufficiently heated and places it in female of wooden mould, fixes wooden slab ofmould to keep sheet in position and inserts male block of mould; sets mould in hand press and manipulates controls to compress material and form material to shape of mould; removes moulded plastics object after specified time-interval by opening mould; examines and gaugesproduct for conformity to plant or customer standards. May make minor adjustments in moulding procedure to eliminate defects, and remould product.

Plastic Products Making Operatives, Other; perform number of routine and low skilled tasks in manufacturing plastics products, such as arranging and loading plastics or plastics impregnated sheets, assisting Printing Machine Operator, cleaning and finishing moulded plastics products etc. and are designated as: Laminating Press Helper (Plastics) if assists Laminating Press Operator by counting sheets of resin impregnated wood, fabric, paper, or other materials, by wiping surface of metal plates with cloth and special solution to prevent sticking, and by stacking sheets between plain or engraved plates.

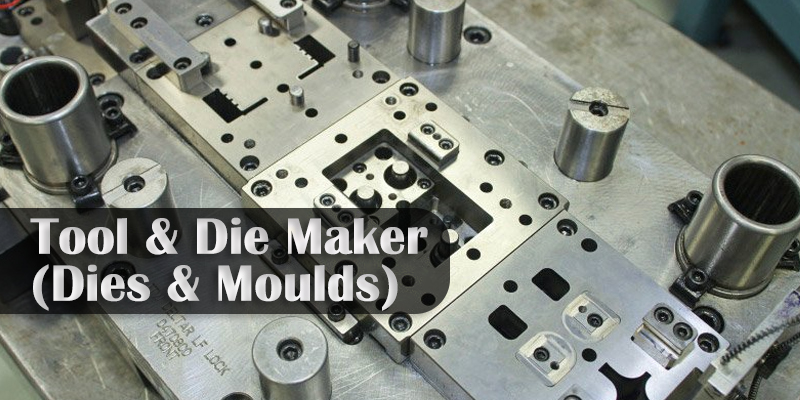

Tool & Die Maker (Dies & Moulds)

1. Introduction:

This course is meant for the candidates who aspire to become a professional Tool and Die maker (Dies & Moulds).

.

2. Terminal Competency/Deliverables:

After successful completion of this course the trainee shall be able to perform the following skills with proper sequence.

- 1. The trainees can work in the industry as semi-skilled Tool and Die Maker (Dies & Moulds).

- 2. The trainee can able to manufacture different components for dies & moulds by operating different machines like lathe, drilling, welding, milling grinding, EDM, Injection moulding and CNC. Inspection & measurement of different components and observing safety precautions while working.

- 3. The trainees can work on Dismantle & assemble of various dies & moulds and test.

- 4. Trainee is able to make simple programme on CNC machine and operate.

- 5. Handle different type of Fire extinguishers.

3.. Employment opportunities:

On successful completion of this course, the candidates shall be gainfully employed in

the following industries:

- 1. Production & Manufacturing industries.

- 2. Structural Fabrication like bridges, Roof structures, Building & construction.

- 3. Automobile and allied industries

- 4. Service industries like road transportation and Railways.

- 5. Ship building and repair

- 6. Infrastructure and defense organizations

- 7. In public sector industries like BHEL, BEML, NTPC, etc and private industries in India & abroad.

- 8. Self employment

ITI Student Resume Portal

रिज्यूम पोर्टल का मुख्य उद्देश्य योग्य छात्रों की जानकारी सार्वजनिक पटल पर लाने की है जिससे जिन्हें आवश्यकता हो वह अपने सुविधा अनुसार छात्रों का चयन कर सकते हैं