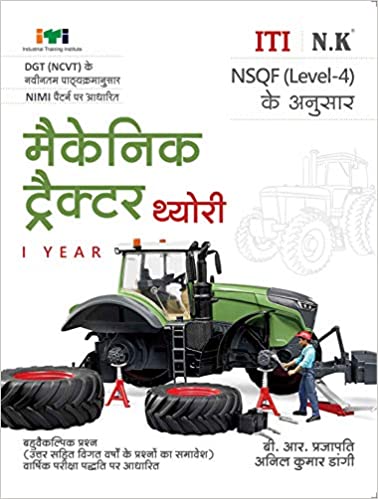

ITI Mechanic Tractor Theory I Year Hindi

Product details

ASIN : B07HC6L99K

Publisher : Neelkanth Publishers; 2019th edition (1 January 2018)

Language : Hindi

Paperback : 760 pages

Item Weight : 1 kg 270 g

Dimensions : 27.5 x 21.5 x 3 cm

Country of Origin : India

ITI Book ITI Mechanic Tractor Theory I Year Hindi is by [node:field_author]. ITI Mechanic Tractor Theory I Year Hindi is according to Latest NSQF Level. ITI Mechanic Tractor Theory I Year Hindi is according to latest syllabus of DGT(NCVT). ITI Mechanic Tractor Theory I Year Hindi is for [node:field_semester]. ITI Mechanic Tractor Theory I Year Hindi is for ITI trade Mechanic (Tractor) . ITI Mechanic Tractor Theory I Year Hindi have fundamental topic [node:field_book_index]

Mechanic (Tractor)

ITI trade Mechanic (Tractor) is powered by NCVT. ITI trade Mechanic (Tractor) is a job oriented trade ITI trade Mechanic (Tractor) is suitable for government job and private job. This ITI trade Mechanic (Tractor) is very powerful for self-empowerment. This ITI trade Mechanic (Tractor) is perfectly design to fulfill industrial requirement of Indian Industries as well as International industries.

The trainee attending the course on ‘Mechanic Tractor’ shall be able to perform basic fitting , grinding, surface finishing, sheet metal, bending, and welding operations and carry out electrical/electronic, nondestructive, and battery tests, in an tractor workshop. The trainee shall be able to service cooling and lubrication systems, intake and exhaust systems, and fuel feed system, of the tractor. The trainee shall also be able to overhaul diesel engine, clutch and gearbox, differential and PTO Unit, steering system, assemblies of power tiller, implements, and charging and starting systems, of the tractor.

Mechanic Tractor repairs and overhauls tractors by various mechanical processes for agriculture, constructional and other heavy duties

Trade Practical (27 Hrs/week)

Familiarisation with institute, Job opportunities in the automobile sector, Machinery used in Trade. Types of work done by the students in the shop floor.

Practical related to Safety and Health, Importance of maintenance and cleanliness of Workshop. Interaction with health centre and fire service station to provide demo on First aid and Fire safety, Use of fire extinguishers. Demonstration on safe handling and Periodic testing of lifting equipment, and Safety disposal of Used engine oil. Energy saving Tips of ITI electricity Usage

Practice using all marking aids, like steel rule with spring calipers, dividers, scriber, punches, Chisel etc., Layout a work piece- for line, circle, arcs and circles. Practice to measure a wheel base of a vehicle with measuring tape. Practice to measure valve spring tension using spring tension tester Practice to remove wheel lug nuts with use of an air impact wrench Practice on General workshop tools & power tools.

Measuring practice on Cam height, Camshaft Journal dia, crankshaft journal dia, Valve stem dia, piston diameter, and piston pin dia with outside Micrometers. Measuring practice on the height of the rotor of an oil pump from the surface of the housing or any other auto component measurement with depth micrometer. Measuring practice on valve spring free length. Measuring practice on cylinder bore, Connecting rod bore, inside diameter (ID) of a camshaft bearing with Telescope gauges. Measuring practice on cylinder bore for taper and out-of-round with Dial bore gauges. Measuring practice to measure wear on crankshaft end play, crankshaft run out, and valve guide with dial indicator. Measuring practice to check the flatness of the cylinder head is warped or twisted with straightedge is used with a feeler gauge. Measuring practice to check the end gap of a piston ring, piston-tocylinder wall clearance with feeler gauge. Practice to check engine manifold vacuum with vacuum gauge. Practice to check the air pressure inside the vehicle tires is maintained at the recommended setting

Practice on General cleaning, checking and use of nut, bolts, & studs etc., Removal of stud/bolt from blind hole. Practice on cutting tools like Hacksaw, file, chisel, Sharpening of Chisels, center punch, safety precautions while grinding. Practice on Hacksawing and filing to given dimensions.

Practice on Marking and Drilling clear and Blind Holes, Sharpening of Twist Drills Safety precautions to be observed while using a drilling machine. Practice on Tapping a Clear and Blind Hole, Selection of tape drill Size, use of Lubrication, Use of stud extractor. Cutting Threads on a Bolt/ Stud. Adjustment of two piece Die, Reaming a hole/ Bush to suit the given pin/ shaft, scraping a given machined surface.

Practice on making Rectangular Tray. Pipe bending, Fitting nipples unions in pipes. Soldering and Brazing of Pipes.

Practice in joining wires using soldering Iron, Construction of simple electrical circuits, Measuring of current, voltage and resistance using digital multimeter, practice continuity test for fuses, jumper wires, fusible links, circuit breakers.

Diagnose series, parallel, seriesparallel circuits using Ohm’s law, Check electrical circuit with a test lamp, perform voltage drop test in circuits using multimeter, measure current flow using multimeter /ammeter, use of service manual wiring diagram for troubleshooting.

Cleaning and topping up of a lead acid battery, Testing battery with hydrometer, Connecting battery to a charger for battery charging, Inspecting & testing a battery after charging, Measure and Diagnose the cause(s) of excessive Key-off battery drain (parasitic draw) and do corrective action. Testing of relay and solenoids and its circuit.

Identify and test power and signal connectors for continuity, Identify and test different type of Diodes, NPN & PNP Transistors for its functionality, Construct and test simple logic circuits OR, AND & NOT and Logic gates using switches.

Practice to make straight beads and Butt, Lap & T joints Manual Metal Arc Welding. Setting of Gas welding flames, practice to make a straight beads and joints Oxy – Acetylene welding Film on Heat treatment process

Practice on Liquid penetrant testing method and Magnetic particle testing method. Identification of Hydraulic and pneumatic components used in vehicle. Tracing of hydraulic circuit on hydraulic jack, hydraulic power steering, and Brake circuit. Identification of components in Air brake systems.

Neelkanth Publishers

Welcome to Neelkanth Publishers or NK as it is popularly known. In the last ten years, we have published more than 1100 titles and editions of text books, solved question papers in different segments including Engineering, ITI,Polytechnic and Skill Development. We believe in making quality books which are easy to understand, have lucid language and have simple and attractive illustrations. Our authors include some of the most well-known names in their respective fields. Though are books are prepared after painstaking and extensive research with numerous revisions for language and content, yet they are affordable for the masses and hence are popular in the entire country.

https://neelkanthpublishers.com/

ITI text and hand books

ITI Student Resume Portal

रिज्यूम पोर्टल का मुख्य उद्देश्य योग्य छात्रों की जानकारी सार्वजनिक पटल पर लाने की है जिससे जिन्हें आवश्यकता हो वह अपने सुविधा अनुसार छात्रों का चयन कर सकते हैं