Engineering Drawing Mechanical Group

ITI Book Engineering Drawing Mechanical Group is by Hemraj Agarwal. Engineering Drawing Mechanical Group is according to Latest NSQF Level. Engineering Drawing Mechanical Group is according to latest syllabus of DGT(NCVT). Engineering Drawing Mechanical Group is for I Year, II Year. Engineering Drawing Mechanical Group is for ITI trade Fitter, Machinist, Machinist (Grinder), Tool & Die Maker (Dies & Moulds), Tool & Die Maker (Press Tools, Jigs & Fixtures), Turner . Engineering Drawing Mechanical Group have fundamental topic Introduction to Engineering Drawing, Lines and Lettering, Geometric Construction and Freehand Sketching of Plane Figure, Dimensioning, Size and Layout of Drawing Sheet, Projection, Symbolic Representation, Scale, Engineering Curves, Projection of Solids, Free Hand Sketch, Rivet and Riveted Joints, Screwed Fasteners, Detail and Assembly Drawing, Screw Threads, Mechanical Fasteners, Pipe Fittings, Gears and Pulleys, Sectioning, Blueprint Reading, Electro Technical Drawing and Symbols, Metal Estimation and Costing

Introduction to Engineering Drawing

- Engineering Drawing

- Importance of Engineering Drawing

- Relationship of Engineering Drawing with Artistic Drawing

- Relationship of Engineering Drawing with other Types of Drawings

- Conventions

- Viewing an Engineering Drawing Sheet

- Methods of Sheet Folding

- Drawing Instruments

Lines and Lettering

- Lines

- Types and Applications of Line as per BIS SP : 46-2003

- Classification of Lines

- Geometrical Aspects of Drawing Lines

- Procedure of Drawing Lines

- Lettering (BIS SP : 46-2003)

- Height and Width of Lettering

- General Rules for Lettering

- Styles of Lettering

Geometric Construction and Freehand Sketching of Plane Figure

- Angles

- Procedure of Drawing Angle

- Triangles

- Quadrilateral

- Circle

- Polygon

- Ellipse

- Freehand Sketching

Dimensioning

- Types of Dimensions

- Elements of Dimensioning

- Method of Dimensioning of Some Common Features

- Rules of Dimensioning

- Arrowhead

Size and Layout of Drawing Sheet

- Basic Principle of Sheet Size

- Selection of Sheet Size

- Layout on Drawing Sheets

- Item Reference on Drawing and Item List

- Revision Table

Projection

- Principle of Projection

- Projection Methods

- Plane of Projection

- Types of Projection

- Conversion of Isometric Views into Orthographic Views

Symbolic Representation

- Symbolic Representation of Fastener

- Symbolic Representation of Bar and Profile Section

- Symbolic Representation of Weld, Brazed Soldered Joints

- Symbolic Representation of Pipe Fitting and Valve Symbols

- Symbolic Representation of Pipe Fitting Joints

- Symbolic Representation of Electrical and Electronic Elements

- General Symbols of Electric Components

Scale

- Representative Fraction

- Different Types of Scales

Engineering Curves

- Conic Section

- Ellipse

- Parabola

- Hyperbola

Projection of Solids

- Classification of Solids

- Positions of the Solids

- Solids with Axis Perpendicular to an RP

- Rules for Deciding the Hidden Lines

Free Hand Sketch

- Measuring and Checking Tools

- Marking Tools

- Striking Tools

- Cutting Tools

- Holding Device

- Assembling Tools

- Mechanic Diesel

- Welding

Engineering Drawing Mechanical

- Holding Devices

- Duct Systems

Rivet and Riveted Joints

- Fastener

- Classificaion of Fastener

- Rivets

- Riveting

- Types of Rivets

- Forms and Proportions of Rivet Heads

- Caulking and Fullering

- Terms and Empirical Proportions of Riveted Joints

- Riveted Joints

- Solved Problems

Screwed Fasteners

- Bolts

- Nut

- Hexagonal Nut and Bolt

- Square Bolt and Washer

- Washer

- Screw

- Locking Arrangements of Nuts

- Foundation Bolts

- Conventional Symbols for Nut and Bolts

Detail and Assembly Drawing

- Detail or Part Drawing

- Assembly Drawing

- Symbols Used to Indicate Surface Roughness

- Roughness Symbols

- Indication of Machining Allowance

- Position of the Specification of Surface Roughness in the Symbol

- Indications of Surface Roughness Symbols on Drawings

- Fits

- Types of Fits

- Expression of a Fit

- Geometrical Tolerance

- Making Assembly Drawing from Details

- Making Detail Drawing from Assembly

- Assembly Drawing of Different Parts

Screw Threads

- Elements of Screw Thread

- Terminology Used

- Classification of Screw Threads

- Applications of Screw Threads

Mechanical Fasteners

- Key

- Taper Pin or Key

- Bolt

- Nut

- Washer

- Screws

- Locking Arrangement of Nuts

Engineering Drawing Mechanical

- Key

- Circlips

- Set Collars

- Taper Pins

- Cotter

- Use of Pins in Connecting Shafts

- Flange Coupling

- Muff Coupling

- Bearings

Pipe Fittings

- Pipe Threads

- Pipe Fitting and Valve Symbols

Gears and Pulleys

- Gear Teeth

- Types of Gears

- Elements of Gears

- Pulleys

- Chamfer

- Fillet

Sectioning

- Types of Sectioning

- Cross Sectional View of Various Objects

- Hatching Techniques

- Sectioning of Complex Objects

- Precautions

- Sectioning Lines for Different Materials

- Orthographic Projection of Sectioned Objects

Blueprint Reading

- Identification of Blueprint Symbols

Electro Technical Drawing and Symbols

- General Symbols

- Graphical Symbols Used for Electrical Installation in a Building

- Electric Wiring Related Symbols According to BIS

- Electrical Circuits and Variabilities Symbols

- Symbols of Variable Resistors

- Identification of Electrical Instruments

- BIS Symbols Related to DC and AC Machine Circuit

- Lettering Codes for Terminal Marking Concerning DC Machines

- BIS Symbols-Switchgear and Accessories

Metal Estimation and Costing

- Metal Estimation

- Costing

ITI Book Engineering Drawing Mechanical Group is by Hemraj Agarwal. Engineering Drawing Mechanical Group is according to Latest NSQF Level. Engineering Drawing Mechanical Group is according to latest syllabus of DGT(NCVT). Engineering Drawing Mechanical Group is for I Year, II Year. Engineering Drawing Mechanical Group is for ITI trade Fitter, Machinist, Machinist (Grinder), Tool & Die Maker (Dies & Moulds), Tool & Die Maker (Press Tools, Jigs & Fixtures), Turner . Engineering Drawing Mechanical Group have fundamental topic Introduction to Engineering Drawing, Lines and Lettering, Geometric Construction and Freehand Sketching of Plane Figure, Dimensioning, Size and Layout of Drawing Sheet, Projection, Symbolic Representation, Scale, Engineering Curves, Projection of Solids, Free Hand Sketch, Rivet and Riveted Joints, Screwed Fasteners, Detail and Assembly Drawing, Screw Threads, Mechanical Fasteners, Pipe Fittings, Gears and Pulleys, Sectioning, Blueprint Reading, Electro Technical Drawing and Symbols, Metal Estimation and Costing

Fitter

ITI trade Fitter is powered by NCVT. ITI trade Fitter is a job oriented trade ITI trade Fitter is suitable for government job and private job. This ITI trade Fitter is very powerful for self-empowerment. This ITI trade Fitter is perfectly design to fulfill industrial requirement of Indian Industries as well as International industries.

Fitters have a wide scope of Employability ranging from self-employment, contractual employment to Industrial jobs. On successful completion of this course, the candidates shall be gainfully employed in the following industries:

- Production & Manufacturing industries.

- Structural Fabrication like bridges, Roof structures, Building & construction.

- Automobile and allied industries

- Service industries like road transportation and Railways.

- Ship building and repair

- Infrastructure and defence organizations

- In public sector industries like BHEL, BEML, NTPC, etc and private industries in India & abroad.

- Self employment

International Comparability

- Existence of any official document suggesting the comparability of the qualification with the qualifications in other countries is not known.

- However, ITI passed out trainees are getting employment in many Gulf countries, European countries, Australia, New Zealand, Singapore etc.

Progression Pathway

- Can appear in 10+2 examination through National Institute of Open Schooling (NIOS) for acquiring higher secondary certificate and can go further for General/ Technical education

- Can take admission in diploma course in notified branches of Engineering by lateral entry

- Can join as semi-skilled worker in the industry and can become supervisor after doing part-time diploma in relevant branch of Engineering

- Can join Apprenticeship programme in different types of industries leading to National Apprenticeship certificate (NAC) after which they will be employed in industry as skilled worker and can become supervisor after doing part-time diploma in relevant branch of Engineering

- Can join Crafts Instructor Training Scheme (CITS) in the relevant trade after which they will be employed in ITI/ Vocational Training Institute as instructor

Machinist

ITI trade Machinist is powered by NCVT. ITI trade Machinist is a job oriented trade ITI trade Machinist is suitable for government job and private job. This ITI trade Machinist is very powerful for self-empowerment. This ITI trade Machinist is perfectly design to fulfill industrial requirement of Indian Industries as well as International industries.

On successful completion of this course, the candidates shall be gainfully employed as:

• Machinist, Grinder, Operator of various types of power driven metal cutting or grinding machines in Production & Manufacturing industries,Infrastructure and defence organizations.

• Machinists have a wide scope of Employability ranging from self-employment, contractual employment to Industrial jobs.

International Comparability

- 1. Comparison Made with German Syllabus and the proposed syllabus is in line with the existing German Syllabus (Around 95% contents are matching).

- 2. However, ITI passed out trainees are getting employment in many Gulf countries, European countries, Australia, New Zealand, Singapore etc.

Progression Pathway

- Can appear in 10+2 examination through National Institute of Open Schooling (NIOS) for acquiring higher secondary certificate and can go further for General/ Technical education

- Can take admission in diploma course in notified branches of Engineering by lateral entry

- Can become supervisor after doing part-time diploma in relevant branch of Engineering.

- Can join Apprenticeship programme in different types of industries leading to National Apprenticeship certificate (NAC) after which they will be employed in industry as skilled worker and can become supervisor after doing part-time diploma in relevant branch of Engineering

- Can join Crafts Instructor Training Scheme (CITS) in the relevant trade after which they will be employed in ITI/ Vocational Training Institute as instructor

Machinist (Grinder)

ITI trade Machinist (Grinder) is powered by NCVT. ITI trade Machinist (Grinder) is a job oriented trade ITI trade Machinist (Grinder) is suitable for government job and private job. This ITI trade Machinist (Grinder) is very powerful for self-empowerment. This ITI trade Machinist (Grinder) is perfectly design to fulfill industrial requirement of Indian Industries as well as International industries.

Machinist Grinder has a wide scope of Employability ranging from self-employment, contractual employment to Industrial jobs. On successful completion of this course, the candidates shall be gainfully employed in the industries for following occupations:

• Grinder, General

• Surface Grinder

• Roll Grinder

• Honer/Honing Machine Operator

• Lapper

• Grinder, Tool and Cutter

• In public sector and private industries in India & abroad.

• Self employment

International Comparability

1. Existence of any official document suggesting the comparability of the qualification with the qualifications in other countries is not known.

2. However, ITI passed out trainees are getting employment in many Gulf countries, European countries, Australia, New Zealand, Singapore etc.

Progression Pathway

- Can appear in 10+2 examination through National Institute of Open Schooling (NIOS) for acquiring higher secondary certificate and can go further for General/ Technical education.

- Can take admission in diploma course in notified branches of Engineering by lateral entry.

- Can join Apprenticeship programme in different types of industries leading to National Apprenticeship certificate (NAC).

- Can join Crafts Instructor Training Scheme (CITS) in the relevant trade after

Tool & Die Maker (Dies & Moulds)

1. Introduction:

This course is meant for the candidates who aspire to become a professional Tool and Die maker (Dies & Moulds).

.

2. Terminal Competency/Deliverables:

After successful completion of this course the trainee shall be able to perform the following skills with proper sequence.

- 1. The trainees can work in the industry as semi-skilled Tool and Die Maker (Dies & Moulds).

- 2. The trainee can able to manufacture different components for dies & moulds by operating different machines like lathe, drilling, welding, milling grinding, EDM, Injection moulding and CNC. Inspection & measurement of different components and observing safety precautions while working.

- 3. The trainees can work on Dismantle & assemble of various dies & moulds and test.

- 4. Trainee is able to make simple programme on CNC machine and operate.

- 5. Handle different type of Fire extinguishers.

3.. Employment opportunities:

On successful completion of this course, the candidates shall be gainfully employed in

the following industries:

- 1. Production & Manufacturing industries.

- 2. Structural Fabrication like bridges, Roof structures, Building & construction.

- 3. Automobile and allied industries

- 4. Service industries like road transportation and Railways.

- 5. Ship building and repair

- 6. Infrastructure and defense organizations

- 7. In public sector industries like BHEL, BEML, NTPC, etc and private industries in India & abroad.

- 8. Self employment

Tool & Die Maker (Press Tools, Jigs & Fixtures)

ITI trade Tool & Die Maker (Press Tools, Jigs & Fixtures) is powered by NCVT. ITI trade Tool & Die Maker (Press Tools, Jigs & Fixtures) is a job oriented trade ITI trade Tool & Die Maker (Press Tools, Jigs & Fixtures) is suitable for government job and private job. This ITI trade Tool & Die Maker (Press Tools, Jigs & Fixtures) is very powerful for self-empowerment. This ITI trade Tool & Die Maker (Press Tools, Jigs & Fixtures) is perfectly design to fulfill industrial requirement of Indian Industries as well as International industries.

During the two years duration, a candidate is trained on subjects- Professional Skill, Professional Knowledge, Engineering Drawing, Workshop Science & Calculation and Employability Skills. In addition to this, a candidate is entrusted to make/do project work and Extra Curricular Activities to build up confidence. The practical skills are imparted in simple to complex manner & simultaneously theory subject is taught in the same fashion to apply cognitive knowledge while executing task.

The course covers the detail aspect of mould making& testing. The broad components covered under Professional Skill subject are as below:

1st Semester– The practical part starts with basic fitting covering components like filing, sawing, drilling, tapping, chipping, grinding and different fits. The accuracy proposed is of ±0.05mm and angular accuracy of 1. Different turning operations on lathe viz., plain, facing, boring, grooving, step turning, parting, chamfering, knurling and different thread cutting by setting the different parameter, are covered in the practical part.

2ndSemester– Different milling operations (plain, stepped, angular, dovetail, T-slot, contour, gear) along with surface & cylindrical grinding to an accuracy of ±0.02mm are covered. In addition, solid modeling of mould in CAD & Pro E taught setting and execution of welding is also a component in this semester.

3rdSemester– Setting, operation and programming of CNC turn centre and CNC machining centre to produce components are performed in this semester. 2D & 3D machining with CAM software is also performed. Manufacture drill jig and fixture is also part of the practical. EDM & wire EDM operation to produce components with an accuracy of ±0.02mm is covered. Construction of blanking and piercing tool is done and testing of same is also performed.

4th Semester– Basic construction of Hydraulic & Pneumatic circuits and basic functioning of electrical circuit and sensors are covered in this semester. Construction of compound and progressive tools is done testing of same is executed. Simple repair and overhauling of different machines viz., drill, milling & lathe is covered. Making of ‘V’ bending tool and draw tool are carried out and testing is also undertaken.

Turner

ITI trade Turner is powered by NCVT. ITI trade Turner is a job oriented trade ITI trade Turner is suitable for government job and private job. This ITI trade Turner is very powerful for self-empowerment. This ITI trade Turner is perfectly design to fulfill industrial requirement of Indian Industries as well as International industries.

After successful completion the passed out trainee

- 1. Can work in the industry as skilled turner.

- 2. Can work in the field of basic fitting, lathe, drilling, Inspection & measurement observing safety precautions.

- 3. Can perform all the turning operations on lathe & perform simple programming & operations on a CNC lathe.

- 4. Can handle different type of Fire extinguishers & personal protective equipment.

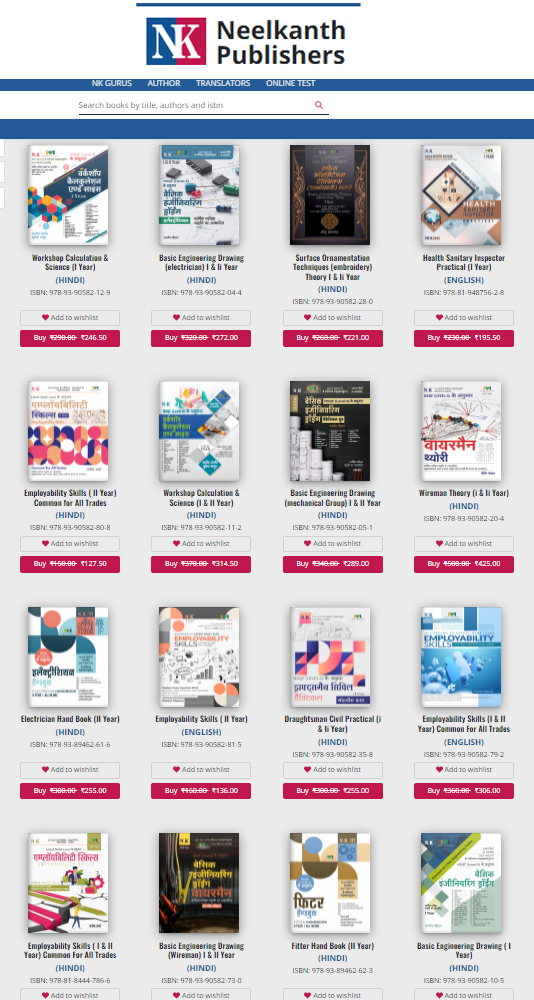

Neelkanth Publishers

Welcome to Neelkanth Publishers or NK as it is popularly known. In the last ten years, we have published more than 1100 titles and editions of text books, solved question papers in different segments including Engineering, ITI,Polytechnic and Skill Development. We believe in making quality books which are easy to understand, have lucid language and have simple and attractive illustrations. Our authors include some of the most well-known names in their respective fields. Though are books are prepared after painstaking and extensive research with numerous revisions for language and content, yet they are affordable for the masses and hence are popular in the entire country.

https://neelkanthpublishers.com/

ITI text and hand books

Introduction to Engineering Drawing

Engineering Drawing

Importance of Engineering Drawing

Relationship of Engineering Drawing with Artistic Drawing

Relationship of Engineering Drawing with other Types of Drawings

Conventions

Viewing an Engineering Drawing Sheet

Methods of Sheet Folding

Drawing Instruments

Lines and Lettering

Lines

Types and Applications of Line as per BIS SP : 46-2003

Classification of Lines

Geometrical Aspects of Drawing Lines

Procedure of Drawing Lines

Lettering (BIS SP : 46-2003)

Height and Width of Lettering

General Rules for Lettering

Styles of Lettering

Geometric Construction and Freehand Sketching of Plane Figure

Angles

Procedure of Drawing Angle

Triangles

Quadrilateral

Circle

Polygon

Ellipse

Freehand Sketching

Dimensioning

Types of Dimensions

Elements of Dimensioning

Method of Dimensioning of Some Common Features

Rules of Dimensioning

Arrowhead

Size and Layout of Drawing Sheet

Basic Principle of Sheet Size

Selection of Sheet Size

Layout on Drawing Sheets

Item Reference on Drawing and Item List

Revision Table

Projection

Principle of Projection

Projection Methods

Plane of Projection

Types of Projection

Conversion of Isometric Views into Orthographic Views

Symbolic Representation

Symbolic Representation of Fastener

Symbolic Representation of Bar and Profile Section

Symbolic Representation of Weld, Brazed Soldered Joints

Symbolic Representation of Pipe Fitting and Valve Symbols

Symbolic Representation of Pipe Fitting Joints

Symbolic Representation of Electrical and Electronic Elements

General Symbols of Electric Components

Scale

Representative Fraction

Different Types of Scales

Engineering Curves

Conic Section

Ellipse

Parabola

Hyperbola

Projection of Solids

Classification of Solids

Positions of the Solids

Solids with Axis Perpendicular to an RP

Rules for Deciding the Hidden Lines

Free Hand Sketch

Measuring and Checking Tools

Marking Tools

Striking Tools

Cutting Tools

Holding Device

Assembling Tools

Mechanic Diesel

Welding

Rivet and Riveted Joints

Fastener

Classificaion of Fastener

Rivets

Riveting

Types of Rivets

Forms and Proportions of Rivet Heads

Caulking and Fullering

Terms and Empirical Proportions of Riveted Joints

Riveted Joints

Solved Problems

Screwed Fasteners

Bolts

Nut

Hexagonal Nut and Bolt

Square Bolt and Washer

Washer

Screw

Locking Arrangements of Nuts

Foundation Bolts

Conventional Symbols for Nut and Bolts

Detail and Assembly Drawing

Detail or Part Drawing

Assembly Drawing

Symbols Used to Indicate Surface Roughness

Roughness Symbols

Indication of Machining Allowance

Position of the Specification of Surface Roughness in the Symbol

Indications of Surface Roughness Symbols on Drawings

Fits

Types of Fits

Expression of a Fit

Geometrical Tolerance

Making Assembly Drawing from Details

Making Detail Drawing from Assembly

Assembly Drawing of Different Parts

Screw Threads

Terminology Used

Classification of Screw Threads

Applications of Screw Threads

Mechanical Fasteners

Key

Circlips

Set Collars

Taper Pins

Cotter

Use of Pins in Connecting Shafts

Flange Coupling

Muff Coupling

Bearings

Pipe Fittings

Pipe Threads

Pipe Fitting and Valve Symbols

Gears and Pulleys

Gear Teeth

Types of Gears

Elements of Gears

Pulleys

Chamfer

Fillet

Sectioning

Types of Sectioning

Cross Sectional View of Various Objects

Hatching Techniques

Sectioning of Complex Objects

Precautions

Sectioning Lines for Different Materials

Orthographic Projection of Sectioned Objects

Blueprint Reading

Identification of Blueprint Symbols

Electro Technical Drawing and Symbols

General Symbols

Graphical Symbols Used for Electrical Installation in a Building

Electric Wiring Related Symbols According to BIS

Electrical Circuits and Variabilities Symbols

Symbols of Variable Resistors

Identification of Electrical Instruments

BIS Symbols Related to DC and AC Machine Circuit

Lettering Codes for Terminal Marking Concerning DC Machines

BIS Symbols-Switchgear and Accessories

Free Hand Sketch

Holding Devices

Duct Systems

Metal Estimation and Costing

Metal Estimation

Costing

ITI Student Resume Portal

रिज्यूम पोर्टल का मुख्य उद्देश्य योग्य छात्रों की जानकारी सार्वजनिक पटल पर लाने की है जिससे जिन्हें आवश्यकता हो वह अपने सुविधा अनुसार छात्रों का चयन कर सकते हैं