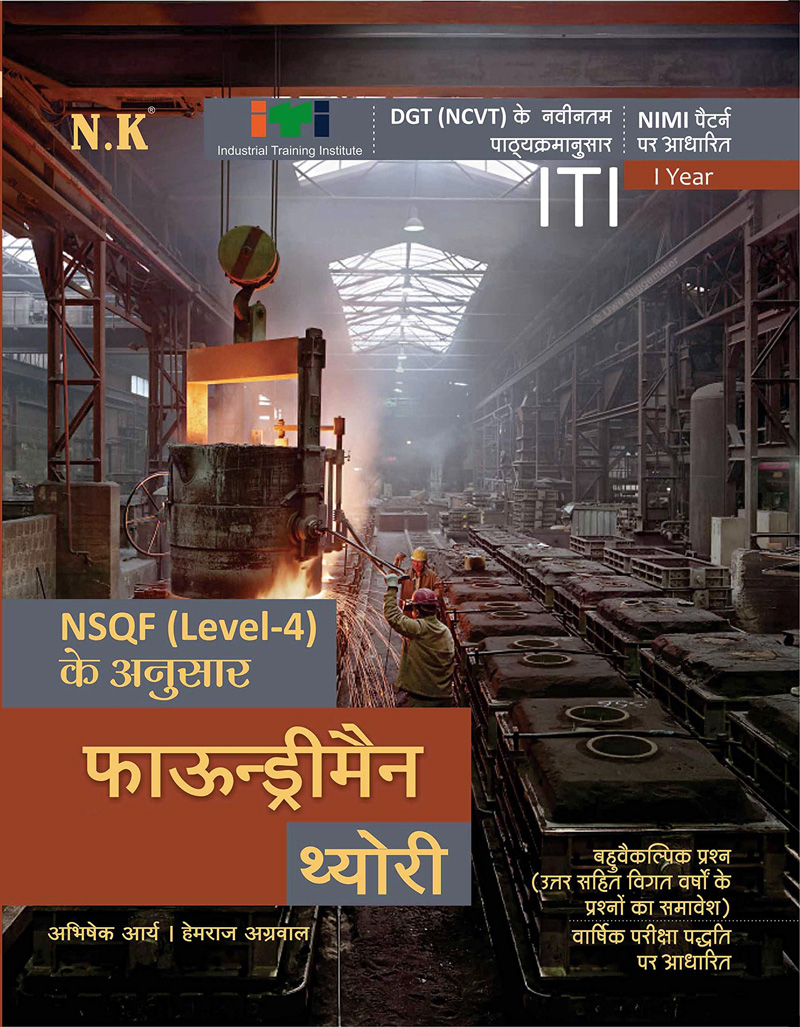

Foundryman Technician Theory Books I Year

ITI Book Foundryman Technician Theory Books I Year is by Abhishek Arya, Hemraj Agarwal. Foundryman Technician Theory Books I Year is according to Latest NSQF Level. Foundryman Technician Theory Books I Year is according to latest syllabus of DGT(NCVT). Foundryman Technician Theory Books I Year is for I Year. Foundryman Technician Theory Books I Year is for ITI trade Foundryman . Foundryman Technician Theory Books I Year have fundamental topic Trade introduction, Occupational Safety and First Aid, Introduction to Foundry, Sand Testing and Casting Process, Carpentry Tools and Joints, Foundry Tools, Mould and Moulding Process, Moulding Sand, Pattern, Core, Gating System, Fuel Fired Furnace, Grinding and Drilling, Moulding and Casting Process, Cleaning and Inspection of Casting, Binders, Ferrous Metals, Non - Ferrous Metals, Fundamentals of Heat Treatment, Furnaces, Estimating and Costing, Foundry Mechanization, Casting Design

Trade introduction - Foundryman

- Rules of institute

Occupational Safety and First Aid

- Occupational Safety and Health

- Importance of Occupational Safety and Health

- Accidents at Workplace

- Safety

- Personal Protective Equipment (PPE)

- First Aid

- Elementary First Aid

- Lifting and Handling Load

- 5’S Concept

- Response to Emergencies

- Fire

- Soft Skills

Foundryman Technician Theory

- Importance of occupational safety and health

- Accidents at work place

- Safety precautions while using hand tools

- Fire

- Causes of fire in workshop and safety planning

- Storage of inflammable materials

- First aid

- Lifting and handling load

- Types of injuries and preventions

- Kinetic method of lifting load

- Correct manual lifting techniques

- Lowering the load

- 5’S concept

- Personal protective equipments

- Respiratory protection

- Points to be remembered for respiratory protective equipments

- Limitations of personal protective equipments

- Technical emergency

- Power failure

- Protection of body

- Hand and arm protection

- Legs protection

- Common safety precautions used in foundry shop

- Soft skills

Introduction to Foundry

- Development of foundry in India

- Importance of foundry industry

- Principle of foundry

- Types of foundry

- Advantages of metal casting

- Quality assurance

- Importance of quality in foundry

Sand Testing and Casting Process

- Moisture content test

- Permeability test

- Clay content test

- Grain fineness test

- Refractoriness test

- Strength test

- Special casting process

- CO2 moulding

- Different types of casting on mould core

Carpentry Tools and Joints

- Measuring tools

- Measuring instruments

- Marking tools

- Cutting tools

- Planning tools

- Boring tools

- Classification of carpentry joints

- Other carpentry joints

Foundry Tools

- Types of tools

- Marking tools

- Measuring tools

- Cutting tools

- Moulding hand tools

- Casting hand tools

- Fettling tools

- Special tools

- Moulding equipments

Mould and Moulding Process

- Types of mould

- Parts of mould

- Moulding processes

Moulding Sand

- Properties of moulding sand

- Principal ingredient of moulding sand

- Classification of sand

- Preparation of moulding sand

Pattern

- Selection of materials for pattern

- Materials used in pattern

- Differences between wood and metal pattern

- Types of pattern

- Pattern allowances

- Pattern accessories

- Pattern colour code

- Care and maintenance of pattern

- Core box

- Core gum and core repairing paste

Core

- Function of core

- Characteristics core

- Types of core

- Ingredients of core sand

- Composition core sand mixer

- Core making

- Core reinforcement

- Core vent

- Setting of core

- Chaplet

Gating System

- Components of gating system

- Function of gating system

- Types of gate

- Feeder

- Directional solidification

- Chill

- Exothermic material

Fuel Fired Furnace

- Cupola furnace

- Crucible furnace

- Safety precautions during work at furnace

- Surface hardening of ductile iron

- Induction furnace

Grinding and Drilling

- Types of grinding operations

- Grinding machines

- Construction of grinding wheel

- Shapes and applications of grinding wheel

- Grinding wheel specifications

- Off – hand abrasion by bench and pedestal grinding

- Wheel dressers

- Dressing and truing of grinding wheel

- Standard marking system for grinding wheel

- Mounting of grinding wheel

- Loading of wheel

- Glazing of wheel

- General grinding defects and their remedies

- Drill

- Designation of drill

- Parts of drill

- Size of drill

- Drill angle

- Drill for different materials

- Drilling cutting speed

- Feed in drilling

- Drilling defects and causes

Moulding and Casting Process

- Moulding

- Casting techniques

- Common casting defects

- Salvaging of casting defects

Cleaning and Inspection of Casting

- Fettling of casting

- Surface cleaning of casting

- Inspection of casting

- Refractory materials

Binders

- Classification of binders

- Flux

- Manufacturing of coke

- Facing material

Ferrous Metals

- Differences between metal and non – metal

- Types of metals

- Physical and mechanical properties of metals

- Iron ore

- Pig iron

- Cast iron

- Manufacturing process of wrought iron

- Metallurgy of grey cast iron

- Manufacturing process of white of chilled cast iron

- Manufacturing process of malleable cast iron

- Manufacturing process of ductile or nodular cast iron

- Manufacturing of steel

- Alloy steel

- Effects of alloying elements in ferrous metals

Non - Ferrous Metals

- Manufacturing of non – ferrous metals

- Manufacturing process of aluminum

- Manufacturing process of zinc

- Manufacturing process of tin

- Manufacturing process of lead

- Manufacturing process of copper based alloys

- Manufacturing process of aluminum based alloys

- Manufacturing process of magnesium based alloys

Fundamentals of Heat Treatment

- Iron – carbon equilibrium diagram for carbon steel

- Inoculation

- Solidification of iron – carbon – silicon alloy

- Microstructure of grey cast iron

- Methods of heat treatment

- Testing of metals

Furnaces

- Different types of furnaces

- Electric furnaces

- Blast furnace

- Rotary furnace

- Open hearth furnace

- Air Furnace

- Converter furnace

- Puddling furnace

Estimating and Costing

- Cost estimating of simple casting of different metals

- Ferrostatic pressure

- Weight required on mould

- Requirement of molten metal

Foundry Mechanization

- Foundry mechanization

- Mechanized foundry

- Classification of material handling equipments

- Mechanized foundry layout

Casting Design

- Correct sequence of casting design

- Functional design

- Simplification of foundry practices

- Metallurgical considerations

- Economic considerations

ITI Book Foundryman Technician Theory Books I Year is by Abhishek Arya, Hemraj Agarwal. Foundryman Technician Theory Books I Year is according to Latest NSQF Level. Foundryman Technician Theory Books I Year is according to latest syllabus of DGT(NCVT). Foundryman Technician Theory Books I Year is for I Year. Foundryman Technician Theory Books I Year is for ITI trade Foundryman . Foundryman Technician Theory Books I Year have fundamental topic Trade introduction - Foundryman, Occupational Safety and First Aid, Introduction to Foundry, Sand Testing and Casting Process, Carpentry Tools and Joints, Foundry Tools, Mould and Moulding Process, Moulding Sand, Pattern, Core, Gating System, Fuel Fired Furnace, Grinding and Drilling, Moulding and Casting Process, Cleaning and Inspection of Casting, Binders, Ferrous Metals, Non - Ferrous Metals, Fundamentals of Heat Treatment, Furnaces, Estimating and Costing, Foundry Mechanization, Casting Design

Foundryman

ITI trade Foundryman is powered by NCVT. ITI trade Foundryman is a job oriented trade ITI trade Foundryman is suitable for government job and private job. This ITI trade Foundryman is very powerful for self-empowerment. This ITI trade Foundryman is perfectly design to fulfill industrial requirement of Indian Industries as well as International industries.

On successful completion of this course, the candidates shall be gainfully employed as:

- Moulder, Die Casting Machine Operator, Core Maker and Annealer in Production & Manufacturing industries.

- Trainees of Foundry man Trade have a wide scope of Employability ranging from self-employment, contractual employment to Industrial jobs

Progression Pathway

Can join Apprenticeship programme in different types of industries leading to National Apprenticeship certificate (NAC) Can join Crafts Instructor Training Scheme (CITS) in the relevant trade after which they will be employed in ITI/ Vocational Training Institute as instructor can become supervisor after doing diploma in relevant branch of Engineering through lateral entry

Neelkanth Publishers

Welcome to Neelkanth Publishers or NK as it is popularly known. In the last ten years, we have published more than 1100 titles and editions of text books, solved question papers in different segments including Engineering, ITI,Polytechnic and Skill Development. We believe in making quality books which are easy to understand, have lucid language and have simple and attractive illustrations. Our authors include some of the most well-known names in their respective fields. Though are books are prepared after painstaking and extensive research with numerous revisions for language and content, yet they are affordable for the masses and hence are popular in the entire country.

https://neelkanthpublishers.com/

ITI text and hand books

Trade introduction

Rules of institute

Occupational Safety and First Aid

Importance of occupational safety and health

Accidents at work place

Safety precautions while using hand tools

Fire

Causes of fire in workshop and safety planning

Storage of inflammable materials

First aid

Lifting and handling load

Types of injuries and preventions

Kinetic method of lifting load

Correct manual lifting techniques

Lowering the load

5’S concept

Personal protective equipments

Respiratory protection

Points to be remembered for respiratory protective equipments

Limitations of personal protective equipments

Technical emergency

Power failure

Protection of body

Hand and arm protection

Legs protection

Common safety precautions used in foundry shop

Soft skills

Introduction to Foundry

Development of foundry in India

Importance of foundry industry

Principle of foundry

Types of foundry

Advantages of metal casting

Quality assurance

Importance of quality in foundry

Sand Testing and Casting Process

Moisture content test

Permeability test

Clay content test

Grain fineness test

Refractoriness test

Strength test

Special casting process

CO2 moulding

Different types of casting on mould core

Carpentry Tools and Joints

Measuring tools

Measuring instruments

Marking tools

Cutting tools

Planning tools

Boring tools

Classification of carpentry joints

Other carpentry joints

Foundry Tools

Types of tools

Marking tools

Measuring tools

Cutting tools

Moulding hand tools

Casting hand tools

Fettling tools

Special tools

Moulding equipments

Mould and Moulding Process

Types of mould

Parts of mould

Moulding processes

Moulding Sand

Properties of moulding sand

Principal ingredient of moulding sand

Classification of sand

Preparation of moulding sand

Pattern

Selection of materials for pattern

Materials used in pattern

Differences between wood and metal pattern

Types of pattern

Pattern allowances

Pattern accessories

Pattern colour code

Care and maintenance of pattern

Core box

Core gum and core repairing paste

Core

Function of core

Characteristics core

Types of core

Ingredients of core sand

Composition core sand mixer

Core making

Core reinforcement

Core vent

Setting of core

Chaplet

Gating System

Components of gating system

Function of gating system

Types of gate

Feeder

Directional solidification

Chill

Exothermic material

Fuel Fired Furnace

Cupola furnace

Crucible furnace

Safety precautions during work at furnace

Surface hardening of ductile iron

Induction furnace

Grinding and Drilling

Types of grinding operations

Grinding machines

Construction of grinding wheel

Shapes and applications of grinding wheel

Grinding wheel specifications

Off – hand abrasion by bench and pedestal grinding

Wheel dressers

Dressing and truing of grinding wheel

Standard marking system for grinding wheel

Mounting of grinding wheel

Loading of wheel

Glazing of wheel

General grinding defects and their remedies

Drill

Designation of drill

Parts of drill

Size of drill

Drill angle

Drill for different materials

Drilling cutting speed

Feed in drilling

Drilling defects and causes

Moulding and Casting Process

Moulding

Casting techniques

Common casting defects

Salvaging of casting defects

Cleaning and Inspection of Casting

Fettling of casting

Surface cleaning of casting

Inspection of casting

Refractory materials

Binders

Classification of binders

Flux

Manufacturing of coke

Facing material

Ferrous Metals

Differences between metal and non – metal

Types of metals

Physical and mechanical properties of metals

Iron ore

Pig iron

Cast iron

Manufacturing process of wrought iron

Metallurgy of grey cast iron

Manufacturing process of white of chilled cast iron

Manufacturing process of malleable cast iron

Manufacturing process of ductile or nodular cast iron

Manufacturing of steel

Alloy steel

Effects of alloying elements in ferrous metals

Non – Ferrous Metals

Manufacturing of non – ferrous metals

Manufacturing process of aluminum

Manufacturing process of zinc

Manufacturing process of tin

Manufacturing process of lead

Manufacturing process of copper based alloys

Manufacturing process of aluminum based alloys

Manufacturing process of magnesium based alloys

Fundamentals of Heat Treatment

Iron – carbon equilibrium diagram for carbon steel

Inoculation

Solidification of iron – carbon – silicon alloy

Microstructure of grey cast iron

Methods of heat treatment

Testing of metals

Furnaces

Different types of furnaces

Electric furnaces

Blast furnace

Rotary furnace

Open hearth furnace

Air Furnace

Converter furnace

Puddling furnace

Estimating and Costing

Cost estimating of simple casting of different metals

Ferrostatic pressure

Weight required on mould

Requirement of molten metal

Foundry Mechanization

Foundry mechanization

Mechanized foundry

Classification of material handling equipments

Mechanized foundry layout

Casting Design

Correct sequence of casting design

Functional design

Simplification of foundry practices

Metallurgical considerations

Economic considerations

ITI Student Resume Portal

रिज्यूम पोर्टल का मुख्य उद्देश्य योग्य छात्रों की जानकारी सार्वजनिक पटल पर लाने की है जिससे जिन्हें आवश्यकता हो वह अपने सुविधा अनुसार छात्रों का चयन कर सकते हैं