Basic Welding Theory (Punjabi)

ISBN 978-93-5216-142-3

TITLE Basic Welding Theory (Punjabi)

AUTHOR D.P. Mishra,,

PRICE 290

DISCOUNT 0%

FINAL PRICE 290

EDITION 2016

REPRINT

NO. OF PAGES 429

SIZES 20*30/8

ITI Book Basic Welding Theory (Punjabi) is by D.P. Mishra. Basic Welding Theory (Punjabi) is according to Latest NSQF Level. Basic Welding Theory (Punjabi) is according to latest syllabus of DGT(NCVT). Basic Welding Theory (Punjabi) is for [node:field_semester]. Basic Welding Theory (Punjabi) is for ITI trade Welder, Welder (Fabrication & Fitting), Welder (GMAW & GTAW), Welder (Pipe), Welder (Structural), Welder (Welding & Inspection) . Basic Welding Theory (Punjabi) have fundamental topic [node:field_book_index]

Welder

Welder (Fabrication & Fitting)

Welder (GMAW & GTAW)

Welder (Pipe)

Welder (Welding & Inspection)

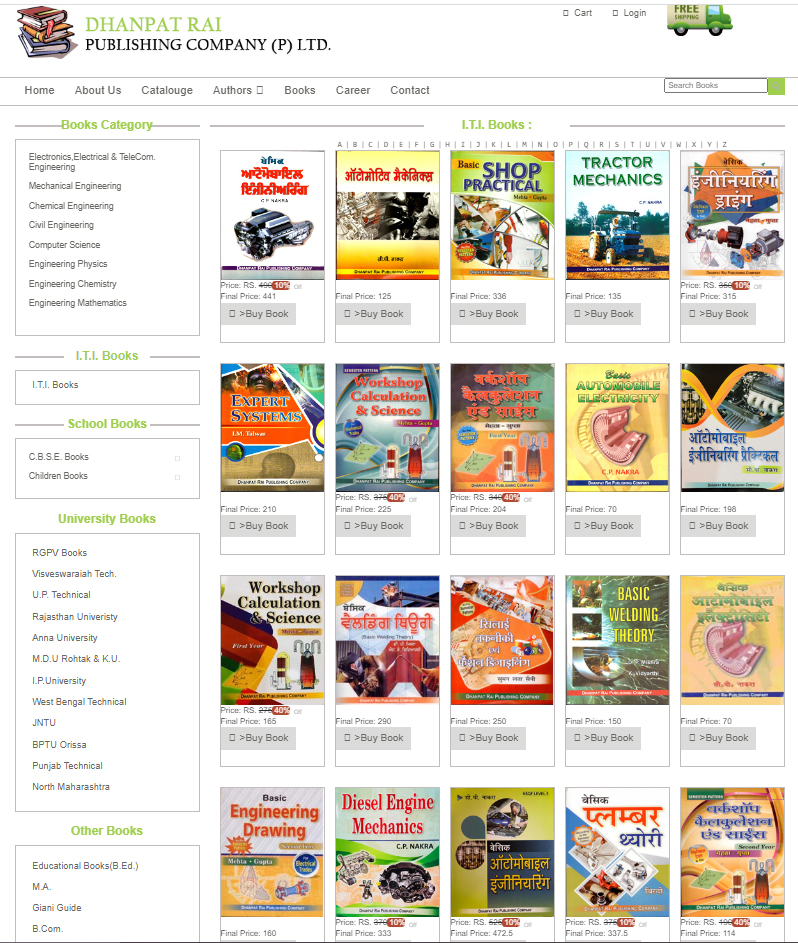

Dhanpat Rai Publications

Dhanpatrai Publishing Company (P) Ltd., established in 1951, has come a long way in making a firm and lasting impression in the field of publications. Dhanpatrai Publishing Company (P) Ltd., has always been contents quality, usefulness, lucid presentation, affordable prices and the choice of subjects those have been the core driving factors of its publishing programs."Meaningful and content-rich titles on a variety of subjects catering to readers and users of all ages and of all sections of the society" have been the mission statement of the publishing house, which is always unmindful of their commercial viability.

Dhanpat Rai Publishing Company (P) Ltd., is also one of the foremost Asian publishing houses to promote new authors and to have established a countrywide network of around 3000 distributors and retailers for its publications, which in itself is the largest dealer network in India for any publishing house. Each and every title on an array of subject interests is hand picked earning the publishing house an enviable reputation in the global arena. The zealously built titles list, content values, subject relevance and spread, practicality of its publications and economy pricing are synonymous with the name Dhanpatrai PCPL, that is enabling India`s foremost publishing house march to the top slot position in Indian textbook and reference books publishing.