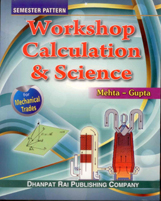

Workshop Calculation & Science (Mechanical)-English

ISBN 978-93-84378-59-2

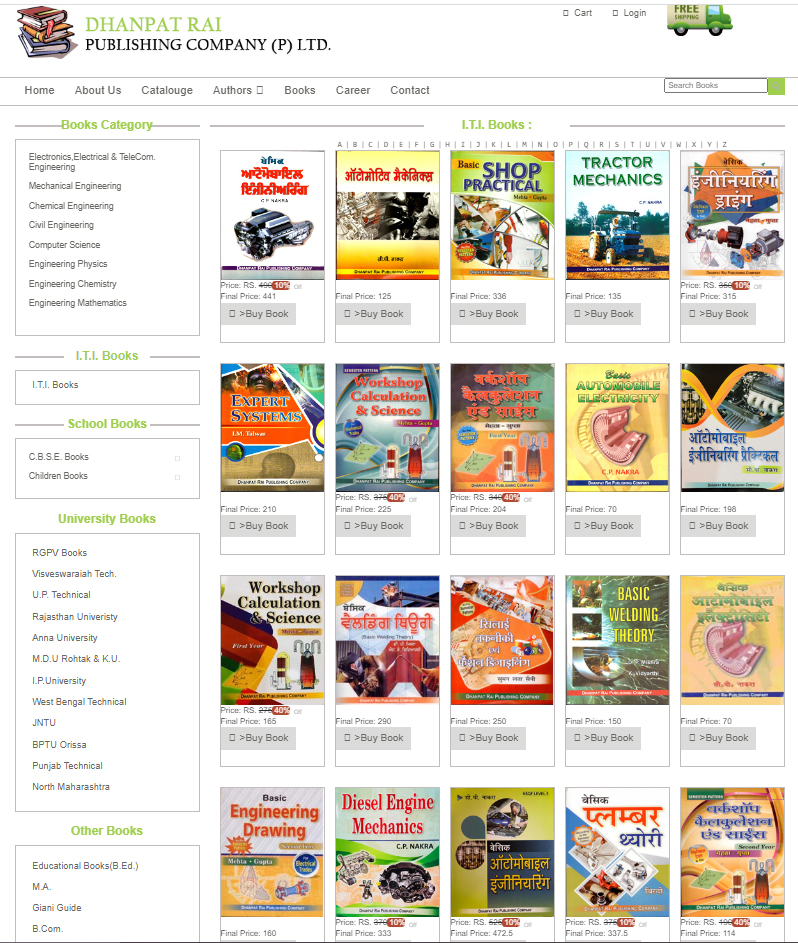

TITLE Workshop Calculation & Science (Mechanical)-English SEMESTER PATTERN

AUTHOR Mehta & Gupta,,

PRICE 375

DISCOUNT 40%

FINAL PRICE 225

EDITION 2008

REPRINT 2018

NO. OF PAGES 315

SIZES 20X30 /8

ITI Book Workshop Calculation & Science (Mechanical)-English is by Mehta & Gupta. Workshop Calculation & Science (Mechanical)-English is according to Latest NSQF Level. Workshop Calculation & Science (Mechanical)-English is according to latest syllabus of DGT(NCVT). Workshop Calculation & Science (Mechanical)-English is for [node:field_semester]. Workshop Calculation & Science (Mechanical)-English is for ITI trade COE-Instrument Mechanic, COE-Maintenance Mechanic, Draughtsman (Mech.), Driver Cum Mechanic, Electronics Mechanic, Instrument Mechanic, Instrument Mechanic (Chemical Plant), Lift and Escalator Mechanic, Lift Mechanic, Machinist, Machinist (Grinder), Maintenance Mechanic (Chemical Plant), Mech. Repair & Maintenance of Light Vehicles, Mechanic (Consumer Electronics), Mechanic (Motor Vehicle), Mechanic (Refrigeration and Air-Conditioning), Mechanic (Tractor), Mechanic Agriculture Machinery, Mechanic Auto Body Painting, Mechanic Auto Body Repair, Mechanic Auto Electrical and Electronics, Mechanic Communication Equipment Maintenance, Mechanic Computer Hardware, Mechanic Consumer Electronics, Mechanic Consumer Electronics Appliances, Mechanic Cum Operator Electronics Communication System, Mechanic Diesel, Mechanic Industrial Electronics, Mechanic Lens/Prism Grinding, Mechanic Machine Tool Maintenance, Mechanic Mechatronics, Mechanic Medical Electronics, Mechanic Mining Machinery, Mechanic Motor Cycle, Mechanic R AC, Mechanic Radio & T.V., Mechanic Two & Three Wheeler, Pump Operator-Cum-Mechanic, Technician Mechatronics, Textile Mechatronics . Workshop Calculation & Science (Mechanical)-English have fundamental topic [node:field_book_index]

Draughtsman (Mech.)

Driver Cum Mechanic

Electronics Mechanic

Instrument Mechanic

Instrument Mechanic (Chemical Plant)

Lift and Escalator Mechanic

Machinist

Machinist (Grinder)

Maintenance Mechanic (Chemical Plant)

Mechanic (Consumer Electronics)

Mechanic (Motor Vehicle)

Mechanic (Refrigeration and Air-Conditioning)

Mechanic (Tractor)

Mechanic Agriculture Machinery

Mechanic Auto Body Painting

Mechanic Auto Body Repair

Mechanic Auto Electrical and Electronics

Mechanic Computer Hardware

Mechanic Consumer Electronics Appliances

Mechanic Diesel

Mechanic Machine Tool Maintenance

Mechanic Medical Electronics

Mechanic Motor Cycle

Mechanic R AC

Mechanic Radio & T.V.

Pump Operator-Cum-Mechanic

Dhanpat Rai Publications

Dhanpatrai Publishing Company (P) Ltd., established in 1951, has come a long way in making a firm and lasting impression in the field of publications. Dhanpatrai Publishing Company (P) Ltd., has always been contents quality, usefulness, lucid presentation, affordable prices and the choice of subjects those have been the core driving factors of its publishing programs."Meaningful and content-rich titles on a variety of subjects catering to readers and users of all ages and of all sections of the society" have been the mission statement of the publishing house, which is always unmindful of their commercial viability.

Dhanpat Rai Publishing Company (P) Ltd., is also one of the foremost Asian publishing houses to promote new authors and to have established a countrywide network of around 3000 distributors and retailers for its publications, which in itself is the largest dealer network in India for any publishing house. Each and every title on an array of subject interests is hand picked earning the publishing house an enviable reputation in the global arena. The zealously built titles list, content values, subject relevance and spread, practicality of its publications and economy pricing are synonymous with the name Dhanpatrai PCPL, that is enabling India`s foremost publishing house march to the top slot position in Indian textbook and reference books publishing.